Editor’s note: this post was meant to be published on Friday 6/14 but was delayed due to a lack of wifi! Saturday 6/15 and Sunday 6/16 will be combined into a big post on my time at La Palma.

Today marked the beginning of a new phase of the Adventure, because today I started really learning about coffee in Colombia. I toured the Devocion Plant in Bogotá all morning and talked to many wonderful people there, attended a cupping at Devocion, and went to La Palma! I’m writing this from the La Palma y El Tucan farm, which I can’t wait to tell you all about.

In this blog post, I’ll try to tell you about my time at the Devocion Plant. But first, I really want to use this post to help explain some of the coffee processing terminology that I’ll be using a lot from here on out in a kind of overview of coffee processing.

A Beginner’s Intro to Coffee Processing Terminology, as Explained by a Beginner

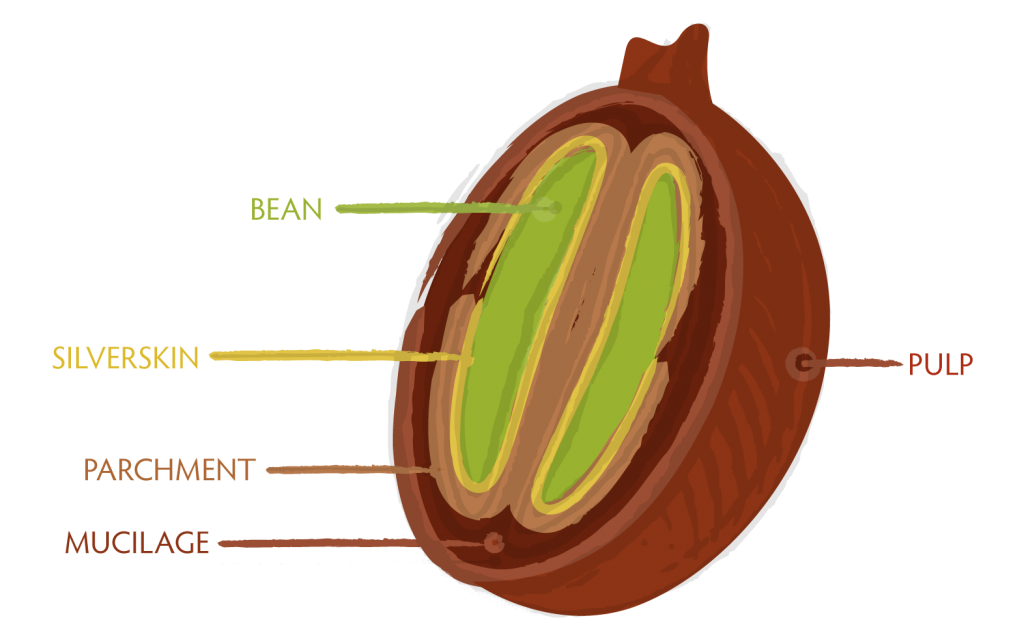

First: what is coffee processing? Coffee is a short tree (some call it a shrub) that grows cherries. Coffee cherries contain seeds, which are coated in a protective shell-like layer called parchment. Underneath the parchment is what we think of as coffee beans. But they’re not brown until you roast them!

Ok, so there is an idea of what the coffee bean looks like. But what happens to it at each stage?

First, the coffee is harvested from the tree. You end up with these big ~100lbs sacks of red coffee cherries. At this point, you get to make your first choice about processing method: whether to bring the cherries to a wet mill or to dry them in the “natural process.”

Natural Processed Coffee

“Naturally processed” (or “dry processed”) coffee refers to coffee that is dried in the cherry. It’s laid directly onto drying beds soon after harvesting. This process adds fruity characteristics to the coffee as the bean absorbs the sugars and organic compounds present in the cherry.

Naturally processed coffees use less water to produce, and often have fruitier characteristics in the cup. This fruitiness is often less sharp and defined as the fruitiness of other processes, because differences between cherries are drawn out through the drying and obscure any singular flavor note. In general, naturally processed coffees are less homogenous in processing, but have a higher sugar content. The coffee cherries are dried until the beans inside have a moisture content of about 10-11%, at which point they’re sent to a dry mill (more on this soon).

The Wet Mill

If you choose not to naturally process your coffee, it goes to a wet mill. A wet mill is a processing station that removes some or all of the cherry from the coffee, leaving the bean in parchment. The wet milling process has several components.

First, the coffee cherries are sent through a pulper, which squeezes the cherry and shoots the beans out. The cherries run off to a compost pile or trash, while the beans collect in a tub. Then, the beans are left in the tub for 12-36 hours to ferment, either with some water in the tub or dry. This fermentation step loosens any remaining cherry mucilage, and allows the beans to absorb some of the sugars of the cherry.

After fermentation, the beans are usually washed in water to remove any remaining mucilage and leave just the cleaned parchment. This is called the “washed process.”

Washed process coffees are generally the cleanest in the cup, with well-defined, sharp flavors. Washed process coffees are also more homogenous in their flavor profile, because the washing removes any variability in absorption of cherry ripeness or sugar content. Most coffee in the world is washed, although almost all coffee from Brazil, the world’s largest coffee producing country, is naturally processed.

A Third Way: Honey Process

So we’ve talked about natural processed and washed process coffees. It turns out that there is a third way to process coffee that is becoming more and more common: the “honey” process. The honey process can be thought of as a balance between natural and washed processes, because it leaves some of the cherry mucilage intact but removes much of it.

Honey processed coffees are also sent through a wet mill, like in the washed process. However, for the honey process, you loosen the plates of the pulper to allow some of the mucilage to remain intact. The coffee is then fermented in a vat. After fermentation, the coffee may be directly transported to drying beds, skipping the washing step.

Honey processed coffees generally have more sweetness than washed coffees. You can choose how much of the cherry mucilage to leave on the coffee, resulting in different flavor profiles. One of the trickiest aspects of processing honey coffee is adequately fermenting it, because of their variability in organic compound content. Some farms use advanced scientific equipment to check the fermentation levels, although this is usually prohibitively expensive.

Drying

After processing, the coffee is left to dry. Coffee must be dried to a moisture content of 10-12% to make it shelf stable before roasting. Usually, the drying process is done via direct sunlight on patios or on raised beds. It is crucial to continually rake the coffee to ensure it dries evenly and reduce the chance of further fermentation or molding.

The Other Mill: The Dry Mill

The next step in the coffee processing story is the dry mill. The dry mill removes all remaining outer layers of the coffee until you are left with the bean and a thin layer of silver skin. After the dry mill, the coffee is ready for roasting.

Natural, honey, and washed coffees can all use the same dry mill. It simply grinds off the outer layers of the bean until only green coffee remains. At Devocion, the coffee is sent through the dry mill twice to ensure no parchment remains on the bean.

Sorting, Packaging, Export

After the dry mill the coffee is very close to being on its way. The last step in coffee processing is sorting, or grading the coffee. This step is crucial to specialty coffee, but is not always implemented for commercial grade coffee. Coffee sorting is usually done by hand, with individuals picking out defective looking beans one at a time from large piles of green coffee.

You may recall from the Q that there are certain tolerances for defects set by the Specialty Coffee Association for green arabica. Graders help ensure the green coffee making it to export meets these tolerances. After graders/sorters finish with the green coffee, it’s ready to be bagged and shipped!

We did it! A very basic overview of coffee processing. I’ll likely reference this blog post every now and then when I’m using obscure terminology, but hopefully you’ll have a better idea of what I’m talking about.

My Day at Devocion

I’ll keep the rest of this post to talking about my time at Devocion, then get to La Palma in the next post. Devocion was amazing! I was scheduled to meet Julia, the Coffee Concierge at Devocion Colombia at 9am. 9am is very early for me but I survived and made it on time. Julia, who luckily is from America (read: speaks English), showed me around all day and answered all the questions I could muster.

We started with a tour of the whole Plant. The Devocion plant is so incredible because it has everything you could ever dream of a coffee factory having. Devocion receives coffee in parchment and they dry mill it themselves in their basement, which is very cool! This allows them to very carefully control the quality of the coffee, and immediately respond to any defects coming in on a per-bag level.

Devocion’s whole schtick is “farm to table” coffee precisely because they dry mill it themselves. The parchment essentially functions as a protective coating for green beans, so once they’re out of the parchment the green bean is exposed to the atmosphere. Devocion is able to serve coffee “from green to cup in 15 days,” which is practically unheard of in the States (but is about on par with most specialty places in Colombia, lol). To achieve this, after milling their coffee they air freight it overnight on Fedex on pallets. I’ve never heard of any other importing company doing this besides the World Coffee Roasting Championships, which is pretty cool!

Devocion’s plant also has an enormous roaster, a packaging station, and a ton of storage for espresso machines, which they wholesale in Colombia.

Devocion’s plant also has a couple other cool parts, like an espresso machine repair shop, an enormous stock of wholesale coffee equipment, and, of course, an impressive quality lab.

Fun espresso repair shop!

An enormous amount of wholesale parts and equipment!

I got super lucky and they were cupping incoming coffees when I was there, and I got to partake in the cupping!

They all knew that I just finished my Q Grader course and were super impressed by it, and I think also happy to have me there. I felt really lucky to get to cup with them, but I also felt like I could actually be helpful! We went through the whole cupping as normal, and I filled out my thoughts on the 5 samples on an SCA form. My scores were pretty closely in line with the group’s consensus with some deviations that I was confident in justifying.

We went around saying scores and flavor notes for each coffee, and it’s always a blast to have everyone agree with your flavor notes. In general, we agreed on the caliber of the different coffees, although my favorite cup – I scored it 85 and it had a super impressive caramel sweetness to me – was not everyone else’s favorite. We all agreed that the 4th sample (C2050 in that picture) was awful and full of defects. The other cuppers just wrote a big X on their scoresheet and said “DO NOT BUY” next to it, which was new to me! I felt obligated to score it properly and subtract the relevant defect points, but I guess it’s probably much nicer to not drink the really bad coffee if you’re not gonna buy it anyways.

After the cupping, Julia and I talked a bit more about what Devocion is up to and their plans. It was super fun to see the company growing and progressing from the Colombian side, as I’ve only ever seen it from NYC.

All in all, I had a wonderful time at Devocion. Not only did I learn a lot about the coffee buying and milling process, production roasting on a huge scale, and supply chain management for a company growing as fast as Devocion, but I really felt like I was able to contribute at the cupping table. It was so fun to feel confident with my cupping spoon in hand and scoresheet filled out, and feel like I had something to say.

After Devocion, I went back to central Bogotá to get ready to go to La Palma. I left for La Palma this afternoon, and got here after a pretty bounce 3-hour drive. La Palma is absolutely incredible, and I am so excited to tell you all about it.

Have a great rest of your weekend, and definitely check out the post tomorrow – La Palma is crazy!

Alex

3 thoughts on “It’s Coffee Time!”